The Kaveri Saga

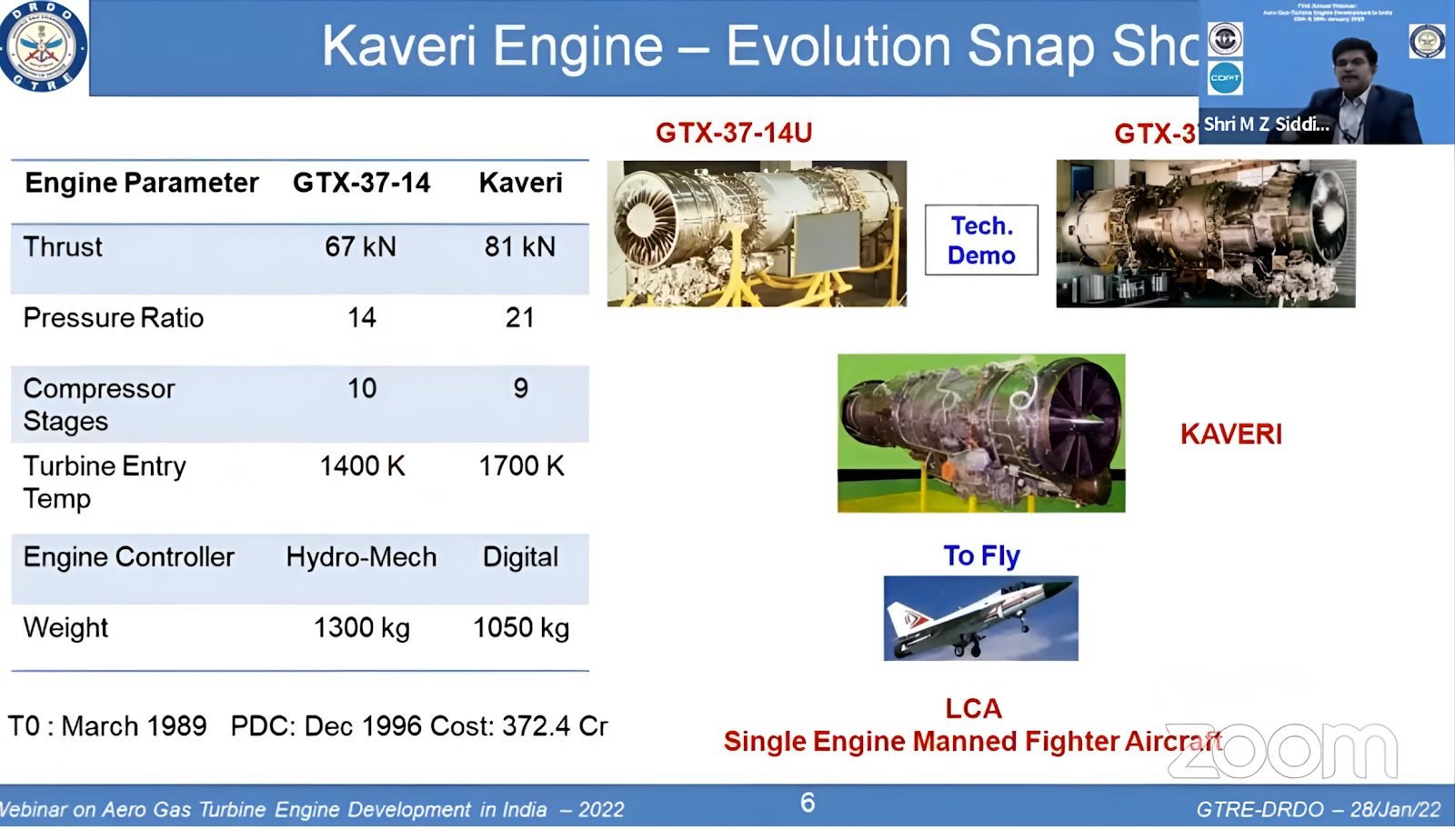

Another low-bypass engine was made called GTX37-14UB with GTX 37-14U as its core, which was an 89 kN Class engine; it was proposed for LCA before Kaveri but was overruled due to its large frontal section. The GTX 37-14U was a flat-rated twin-spool turbojet having a throttle ratio of 1.13 and a bypass ratio of 0.2:1.

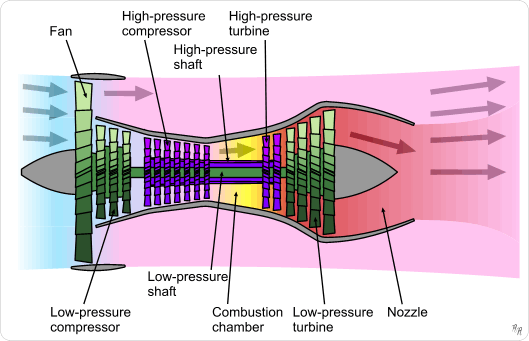

In simple terms, twin spool means. A two-spool engine features two concentric shafts that rotate at different speeds: one links the high-pressure turbine stages to the high-pressure compressor, while the other connects the low-pressure turbine stages to the low-pressure compressor and fan.

|

| A Twin-Spool Engine Diagram |

A low bypass means an engine where the amount of air bypassing the engine core (Bypass Flow) is relatively small compared to the amount of air that passes through the core (Core Flow).

- Compressor: 3 Low-Pressure Compressor Stages | 6 High-Pressure Compressor Stages with variable inlet stator vanes on the first 2 stages.

- Turbine: 1-stage LPT and 1-stage High-Pressure Turbine and Low-Pressure turbine using DS both blades at the start.

- Convergent-divergent short annular system with step diffuser combustion: A nozzle with converging and diverging sections, a compact ring-shaped combustion chamber, and a diffuser with steps to manage airflow and pressure

One day in March 1988, Arunachalam told me that I should come to DRDO Head Quarters to take up the position of Chief Controller R&D. I resisted initially as this was a pure desk job, but I yielded. At one stage, I was assisting more than half of the technical laboratories. I was also in charge of the human resources development. But, I got bored doing this desk job as CCR&D and requested Arunachalam to send me back to a laboratory. He gave me a couple of options and 1 chose to be posted as Director of the Gas Turbine Research Establishment at Bangalore with effect from 1 January 1990. I was not a gas turbine specialist, but materials problems of the engine contributed to more than 50% in the engine development. Kaveri design incorporated the use of a variety of nickel base superalloys and titanium alloys. Thus, I was sure of making my contributions in the development of the engine.

Unlike NCML, GTRE, a major systems laboratory had more than 1500 employees and a strong employees union. It had built the after burner for the Orpheus 703 engine, but that was not accepted because it was over-weight. It had built two technology demonstrator engines designated GTX 37-14U and GTX 37-14UB, the former being a straight jet, while the later a bypass version. This had given confidence to GTRE to bid for building the flat rated gas turbine engine (Kaveri) for the Light Combat Aircraft. The design of the Kaveri engine was based on a mixture of eastern and western philosophies. Obviously, several problems did surface. Prior to my joining GTRE, reputed jet engine manufacturers like Rolls Royce, Snecma and General Electric had shown interest in participating in our engine development programme, but that was turned down due to some reason or other. After my joining GTRE, Mr. Peter Chipporus, a retired chief designer from GE came for discussions and based on his suggestion, the number of stages in the high pressure compressor was increased from 5 to 6. Also, it was brought out that the engine design dimensions specified correspond to the operating conditions and one needs to take into account thermal as well as centrifugal expansion to arrive at the dimensions for manufacturing. Another problem pertained to dimensional distortion due to residual stresses arising out of welding/machining. I assisted in developing a step wise annealing schedule to reduce the distortion to the minimum.

Most of the superalloys required for the manufacture of various discs and blades were initially imported, but later MIDHANI developed all the alloys which were certified by CEMILAC, the agency for certification of materials for air-worthiness. From the designers' point of view, it was necessary to generate adequate data of the materials in use and hence a separate facility, Aeronautical Materials Testing Laboratory, was established near Midhani.

While most of the engine testing facilities was available, we had to go overseas to get some specialized testing done. Russia offered these tests at a lower cost, but procedural delays were considerable. GTRE had 5 engine test beds and it used to test the prototype only once a day. I suggested that it has to be done more number of times a day, as otherwise we may not be able to meet the project schedule. And it was done. My moment of happiness was when the first prototype of Kaveri was test run in 1994.

| Specification | Value | Specification | Value |

|---|---|---|---|

| Power Plant For | TEJAS (LCA) | Engine Type | Twin Spool, Low Bypass |

| Air Mass Flow | 78 kg/sec | Bypass Ratio | 0.16 - 0.18 |

| Overall Pressure Ratio | 21.5 | TET (Turbine Entry Temp.) | 1487 - 1700 K |

| Max Thrust (Dry) | 52 kN | Max Thrust (Afterburner) | 81 kN |

| SFC (Dry) | 0.78 kg/hr/kg | Max SFC with Afterburner | 2.03 kg/hr/kg |

| Thrust-to-Weight Ratio | 7.8 |

- U Certain critical and crucial activities for successful development of Kaveri, viz. development of Compressor, Turbine and Engine Control System, have been lagging behind despite increase in cost by Rs 186.61 crore - CAG Report No. 16 of 2010

- GTRE has been unable to freeze the design of the turbine blades, the compressor has witnessed mechanical failure in performance and the engine control system is not flight-worthy. - CAG Report No. 16 of 2010

- The Kaveri engine which is designed to meet the conditions of operating fighters in the Indian environment is perhaps technologically more challenging than the airframe.

The main issues with Kaveri engines were blade flutter, screeching noise, and afterburner oscillations. There were also problems with the low-pressure compressor, which is why the entire frontal section was redesigned for KDE. The problem with the fan was that of efficiency surge margin and flutter; for HPC, it was blade high-cycle fatigue failure and shortfall of performance compared to what was expected. For combustors it was pressure loss, pattern factor, and structural integrity; for afterburners it was screech, thrust boost, and buckling. At the time of writing this article, all the problems are mostly solved. The issue with afterburner instability was with the fuel spray nozzles, and mostly the afterburner was stretched.

We have also developed a TBC coating unit with ARCI, Hyderabad, and DMRL for yttria-stabilized zirconia coating. The project is more or less in research mode and has not been used for production yet. The SX blades in KDE does use TBC coating, but it is applied by some other machine. ARCI has also developed 150 kW Axial Suspension Plasma Spray, an alternative method for TBC. GTRE is also using EDM machines from Makino for cooling holes.

Talking about single-crystal blades, the HAL makes single-crystal blades for AL31FP engines, which power the Su-30MKI of the IAF, using the Bridgman–Stockbarger technique. The AL31 engine is 53% by cost indigenous and 87% of the components. One can imagine the disks and raw materials are still being imported. A contract was signed with HAL to make 240 AL31FP engines to overhaul Su-30s. The indigenous content will climb to 63% and average 54%.

In the fully heat-treated condition, DMS4 offers more than 80°C metal temperature advantage over the first generation single crystal superalloy CMSX2 and about 8°C advantage over modern third generation alloys such as CMSX10

Fully solutionized between 1315°C - 1360°C over 24 hours with a heat treatment window of 20°C.

Shows superior 1% creep strength and creep rupture life comparable to CMSX10.

Alloy: DMS4M

Solution Heat Treatment:

- 1340°C for 5 hours

- 1350°C for 5 hours

- 1355°C for 10 hours

- 1360°C for 15 hours, followed by air cooling

First Aging Heat Treatment:

- 1160°C for 6 hours, followed by air cooling

Second Aging Heat Treatment:

- 870°C for 20 hours, followed by air cooling

Third Aging Heat Treatment:

- 760°C for 30 hours, followed by air cooling

Now the question is why aren’t we using DMS4 if we have it? I think it was because the goal was never the performance; Kaveri already had a lot of trouble back in 2010, and they were dealing with it, and on top of it, introducing an untested, new material in the engine would have complicated their already very complicated problems. Since they have chosen tried and tested CMSX4, a second-generation alloy to be used in HPT of KDE. The Kabini was using Supercast 247A; maybe that's been replaced with the superior DMD4 alloy. Kaveri was also using Superni 718A for HPC. MIDHANI has also developed the Superni-115 LPT blade blank, although it can't be confirmed if Kaveri is using it or not.

DMRL has also made low-pressure turbine blisks for STFE engines. DMRL has also worked on serpentine air cooling for SX blades.

Today, India has all the building blocks to make its own 4th-gen engine with many PSUs and private players being the first-tier suppliers for global OEMs. A lot of work is being done on composite materials to sustain temperatures as high as 2000°C. Other than GTRE, there is also the Aero Engine Research and Design Center (AERDC) of HAL's engine R&D wing, which has developed the HTFE-25 and HTSE-1200 engines, although the technology is a generation older than what is used in Kaveri. Then there is also MIDHANI, which has developed a wide range of materials since the program began, including materials like Inconel 718.

👌👌

ReplyDeletegood info

ReplyDeleteThanks for the info. Crazy complicated machiner that requires decades of development.

ReplyDelete